When we talk about EV (Electric Vehicle), we mostly refer to electric cars which are quite common these days. You might already be driving an electric car by Tesla, Audi, Honda, Kia, BMW, Volkswagen, Renault, Jaguar, Peugeot or Porsche etc. Almost all car makers are now making electric cars.

For electric propulsion, cars get power from batteries. Bigger and better batteries give not just more power to electric cars but also make them run for more miles. Carrying heavy batteries may not be an issue for an electric car but it can be a problem for electric aircrafts and this is the problem we are going to dig further.

Since electric aircrafts are meant to fly so they must have powerful yet light-weight electric propulsion system (including motor and inverter). Currently available batteries are good for short flights but longer flights are more challenging because you need more power to fly longer and if you increase power by adding more batteries, it will increase the weight of aircraft making it impractical for flying. So, power and weight have to be balanced for electric aircraft motors. In short, we need High Power Density motor drives for electric aircrafts that are light-weight but store more power.

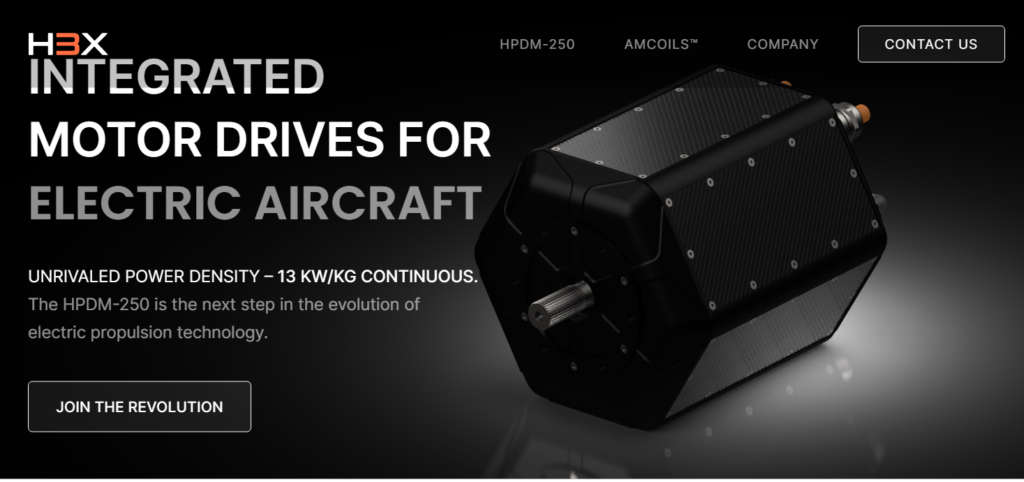

To address this problem, H3X Technologies has built HPDM-250, an Ultra High Power Density (UPHD) motor drive for electric aircrafts with patented technology (patent pending) that gives 250kW of power in just 15KG package.

H3X is a Y Combinator W21 batch graduate founded by Jason Sylvestre (CEO), Max Liben (CTO) and Eric Maciolek (COO). Its innovative HPDM-250 motor drive packages motor and inverter (+ gearbox which is optional) inside with the unmatched power density of 15kW/KG. When we say that both motor, inverter and even the gearbox are packaged in a single unit, it feels little different because mostly these parts are not integrated together to counter the heat issue which is common since all electric parts produce heat while running.

However, H3X’s innovative design and technology allows integrating motor, inverter and gearbox together in a single unit without compromising on quality and power with its:

- Optimized electromagnetics design

- Innovative 3D printed copper stator coils, a patented technology (patent pending) registered as AMcoils trademark that reduce heat by fitting more copper in less space

- Single synergistic cooling jacket to cool motor and other electric parts

- High frequency SiC (Silicon Carbide) power electronics

- Thermal resistance reduction and

- Powerful fault tolerant system.

For any inquiries about HPDM-250 and AMcoils, feel free to contact H3X.